Description

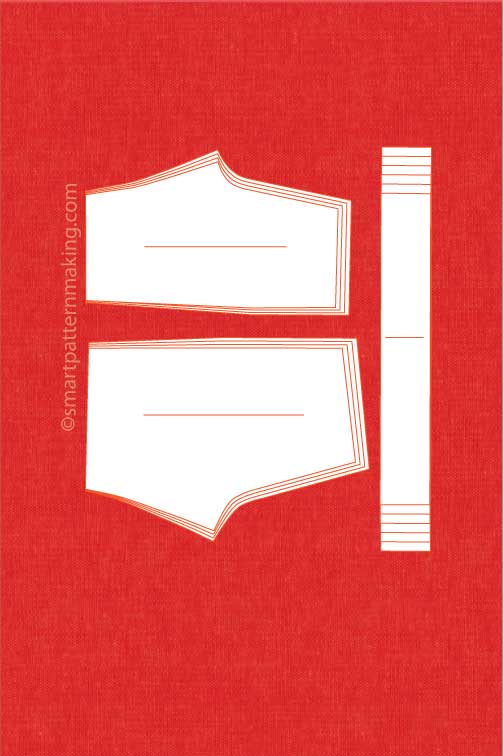

Reliable Shorts Pattern Grading Services for All Your Designs

Inconsistent sizing leads to ill-fitting shorts, wasted materials, and costly reworks—problems that can delay production and hurt your brand’s reputation. At Smart Pattern Making, we ensure that your shorts fit perfectly across all sizes, maintaining their original proportions and design integrity. Whether you're designing cargo shorts, Bermuda shorts, camo shorts, or running shorts, our expert grading team is here to help.

Why Top Designers and Brands Choose Us

- Flawless accuracy – Every resize is executed with precision to maintain fit and balance across shorts styles such as spandex shorts, volleyball shorts, and golf shorts.

- Seamless production integration – Delivered in Gerber, DXF, and industry-standard formats.

- Custom grading rules – Tailored to your unique design specifications for various types of shorts, including board shorts, sweat shorts, yoga shorts, and more.

- Fast turnaround – Get your graded patterns quickly to keep production on schedule.

- Cost-effective – Avoid in-house grading expenses and software costs.

How It Works

- Count your pattern pieces – Identify the number of pieces in your shorts design and select the appropriate grading option.

- Select sizes – Choose the total number of sizes needed to cover your target market.

- Place your order – Add your selections to the cart and complete checkout.

- Upload your files – After confirmation, submit your Gerber or DXF files with grading specifications.

No Grading Specs? We’ve Got You Covered

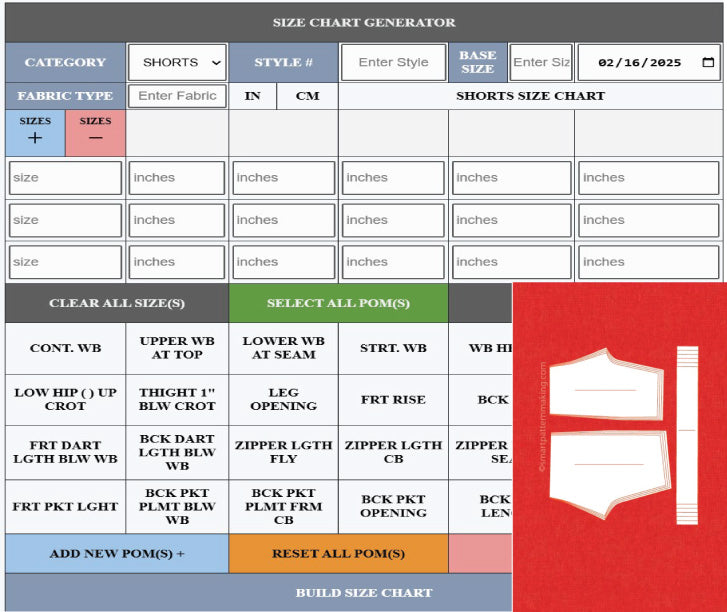

Use our Interactive Shorts Size Chart Generator to create custom grading specs in minutes.

- Define your fit – Enter key measurements: waist, hip, inseam, and leg opening.

- Instantly generate POMs (Points of Measurement) for your shorts – No manual calculations needed.

- Seamless integration – Apply your specs directly to your pattern grading order.

The Hidden Costs of In-House Pattern Grading

Many brands assume keeping pattern grading in-house is more cost-effective, but the reality often shows otherwise. With our professional grading service, you save on in-house costs like hiring, training, and purchasing expensive software and hardware.

| Description | In-House Pattern Grading | Our Professional Grading Service |

|---|---|---|

| Time investment | High – Hiring, training, managing staff | Low – We handle everything |

| Customization | Limited by in-house expertise | Fully tailored to your needs |

| Pattern grader salary | $50,000 - $70,000/year | Included in our service |

| Software purchase | $10,000 - $12,000 | No additional cost |

| Hardware costs | $8,000 - $10,000 | No additional cost |

| Maintenance, paper, and ink | $1,500 - $3,500/year | No additional cost |

| Training and support | $1,500/year | No additional cost |

| Software updates | $1,500/year | No additional cost |

| Total Annual Cost | $72,000 - $107,000+ | Only pay for what you need |

Why spend $100K+ per year on in-house grading when you can get expert precision without the overhead costs?

Frequently Asked Questions

Q: Will my shorts maintain their original fit and proportions?

A: Yes. Our advanced grading techniques ensure your design integrity is preserved in every size, whether you're working on yoga shorts, board shorts, or other specialized designs.

Q: Can you handle complex, detailed, or structured shorts designs?

A: Absolutely. Our expert pattern graders are skilled at handling complex designs like ruffle shorts, ensuring every detail is kept intact during grading.

Q: How long does grading take?

A: Turnaround times depend on the complexity of your design and the number of sizes, but we prioritize fast, precise results to keep your production on track.

Q: What if I need revisions after the grading is complete?

A: We understand that adjustments may be necessary. Our service includes revisions to ensure your patterns meet your exact specifications. Just let us know what changes are needed, and we’ll take care of it quickly.

Q: Are your graded patterns production-ready?

A: Yes. Our graded patterns are compatible with Gerber, DXF, and all major manufacturing systems, ensuring smooth integration into your production line.

Q: Why should I outsource instead of hiring in-house?

A: Outsourcing to us saves you high overhead costs, including salaries, software, and training. You get expert results without the need to invest in costly in-house resources.

Get Your Patterns Graded Now – Keep Your Production on Schedule

Delays cost money, and inaccurate grading can set back an entire collection. Every day you wait is another day lost in production.

Digitizing Policy

Shipping Address

Download Terms and Conditions

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.