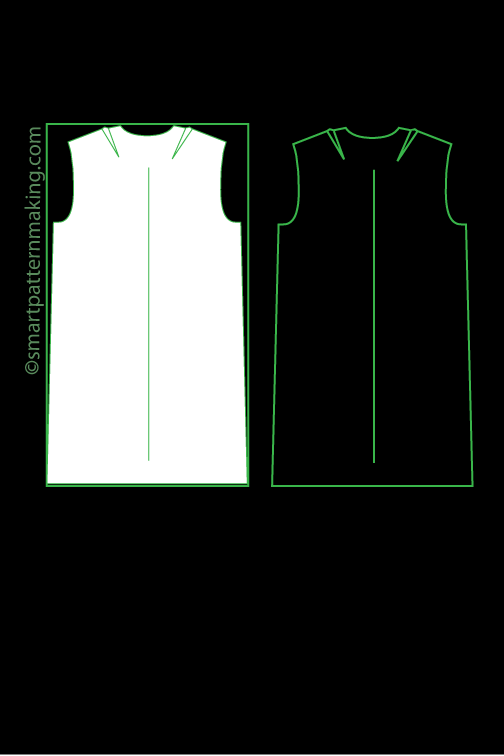

The ability that technology has developed to give us flexible, editable patterns out of those made upon physical materials such as paper, cardboard, and plastic. If you have rendered a pattern onto a physical medium, you can turn it into a digitized pattern that may be edited and adapted across a range of materials and body figures. It has essentially expanded avenues that were previously inaccessible by helping you create one pattern that can further be adapted across whatever apparel idea you have. The textile industry has used pattern digitizing to create clothing lines across different materials, edit patterns, and be inclusive in terms of what sizes they include.

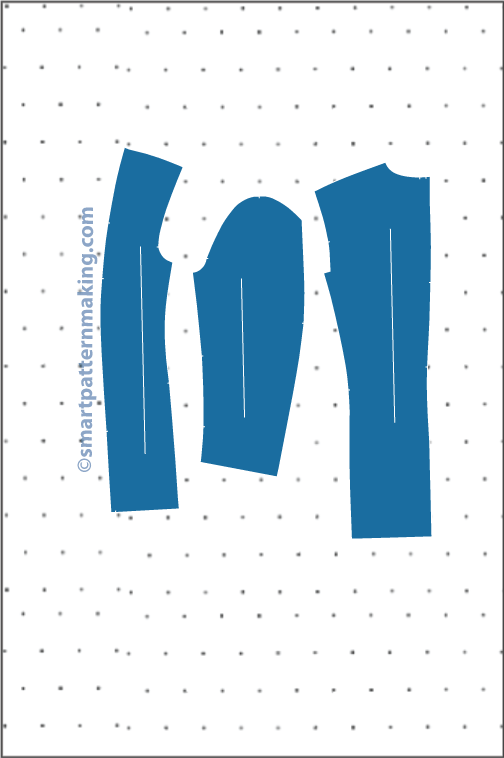

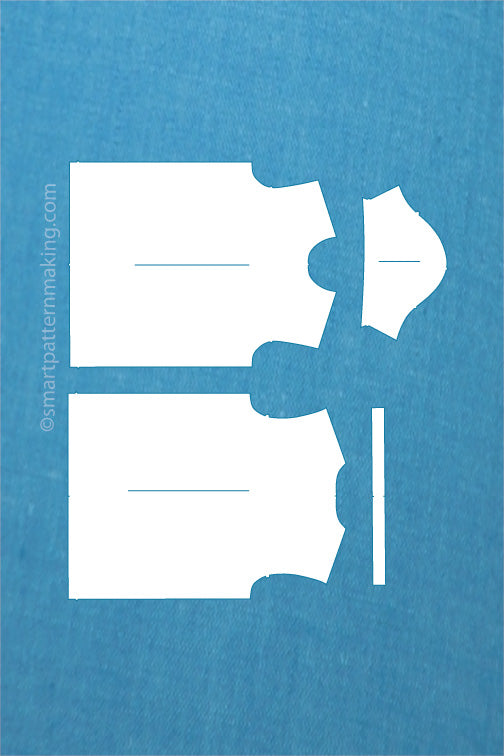

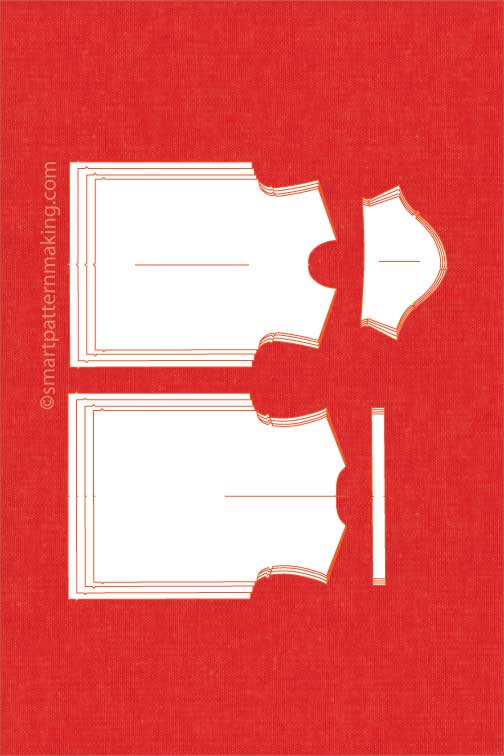

In order to fully appreciate what CAD pant pattern digitizing sofware can achieve, it is important to understand how this technology works. Patterns for sewing are usually crafted in the form of paper, cardboard, or even plastic. In this case, you have a pattern upon which you can begin sewing. However, the limitations of a design made upon paper, plastic, and cardboard is that it can be only made into the dimensions of the existing design. Moreover, if you feel like making edits or changes to the design, you will not be able to do that without massively altering the original design.

This is where pant pattern digitizing software comes in. With the help of a CAD pant pattern digitizing system, you can make a digitally rendered design. The technology for digitally rendering pattern designs is not only limited to textile. The idea of the power of this technology is clear when you see industries that are wide and varied, from automobiles, aviation, and marine to upholstery, textile, and even steel. The technology is an invaluable invention as it allows for ideas that formulate inside the minds of designers and tailors to take place in the real world.

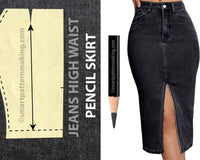

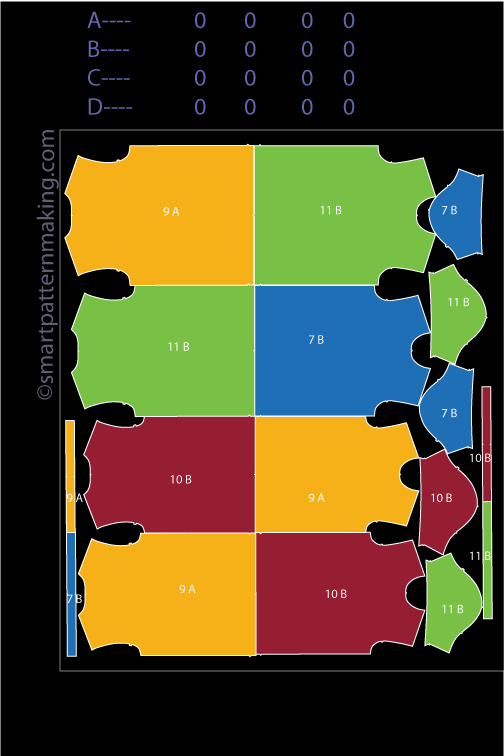

The technology for pants pattern digitizing does not stop there. It goes above and beyond just giving you an editable design. The pattern you digitize can be used to create a variety of sizes that suit different body types, sizes, and figures. It is invaluable to anyone who aims to make a venture into the world of apparel because it offers them not only a room to make mistakes, but also to widen their horizon by creating clothing lines that are inclusive of all kinds of sizes. With the use of CAD pants pattern digitizing technology, your patterns can be digitized accurately and cleanly without the room for human error.

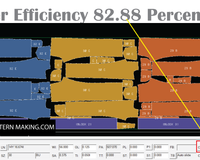

In particular when we talk about pants pattern digitizing, let us take a look at how this process is undertaken in the garment industry. Digitizing in the apparel industry is the procedure through which designs that may be in the form of paper, plastic, or cardboard are scanned accurately and rendered in a digital form. They are scanned into a computer CAD system. This helps ensure that the design retains its essence by maintaining the original design and its shape. This can be preserved as it is or it can be adapted to be edited later on. Not only does this digital rendering help in developing design patterns, it also helps in adapting patterns to different sizes. Sewing patterns made on paper can be rendered digitally and graded through a computer CAD system. These patterns can later on be used to be create a series of sizes for the same design that suit a variety of body shapes, meeting the specific requirements of customers and the market as a whole.

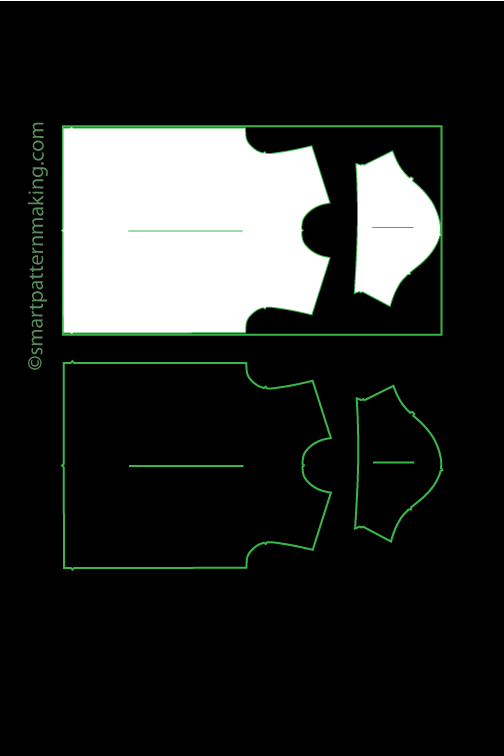

So now you have a pant pattern that you want to digitise, you have to get your equipment in order. The resources you will need for digitizing are straightforward. The process relies upon scanning the pattern and using a computer CAD and CAM software to render it digitally. In order to scan your patterns accurately, use anything from a choice of three types of scanners.

Digitizing tables, also known as table digitizers, are special use tables intended for pattern digitizing. They are lined with electromagnetics which can be used with their companion special mouse to help trace the outlines of patterns, navigating from point to point, one at a time. The special mouse comes equipped with a series of buttons which help you navigate through the CAD and CAM program. The program is directly linked to the digitizer which creates the pattern digitally.

The table digitizers may present you with its own set of problems, but those can be easily remedied with the use of roll up digitizers. Roll up digitizers address the purpose as the table digitizers. The difference is that roll up digitizers are thin, lightweight, and flexible. This awards them with the advantage of being handier than their table counterparts. The roll up digitizer can be stretched out upon a flat surface, and rolled up once the process is finished. Another benefit that roll up digitisers offer is that they cost less in comparison with table digitizers. They do, however, require a flat surface upon which they can be rolled across. However, the issue of speed remains as the speed of digitising is as slow as it was with table digitizers.

After making use of the scanners, it comes to the point where you develop your image in a software there are a series of steps that you need to follow in order to successfully render a digital design of your pattern. The first step is to ensure that the hard copy you have made of your design on paper, cardboard, or plastic is sufficiently flat and your pattern is visible with the use of solid, hard lines that can be scanned accurately.

The second step involves information. This includes information such as grainlines as well as descriptions. These must accompany every piece. It is a wise measure to take your time to record every relevant piece of information as regards the pattern piece. This will serve as a standard to keep track of your progress, without losing essence of the original pattern.

The third step involves the inclusion of a pattern card. The pattern card will include the information you have recorded regarding the pattern. This step is most helpful if you are using a digitizing house for your digitizing needs as it will help them keep a record of all the pieces used in the pattern.

Ready to start digitizing or scanning your patterns? Click the get started button below. We are apparel industry pattern digitizing experts with 25 plus year experience in pattern digitization and scanning services.

Alejandro Esparza: Entrepreneur/ Founder @ smartpatternmaking.com/ Designer/ Professional Pattern Maker/ Startup Advisor. He has the ability to work with small entrepreneurial companies’ private label customers and large organizations. Alejandro is a graduate of Los Angeles Trade Technical College Fashion Design Program. He is an expert with over 25 years experience in apparel garment industry and has published multiple articles about the garment industry. Copyright © by Alejandro Esparza. All Rights Reserved. No part of this article may be copy or used without written Permission from Alejandro Esparza the Author.

---