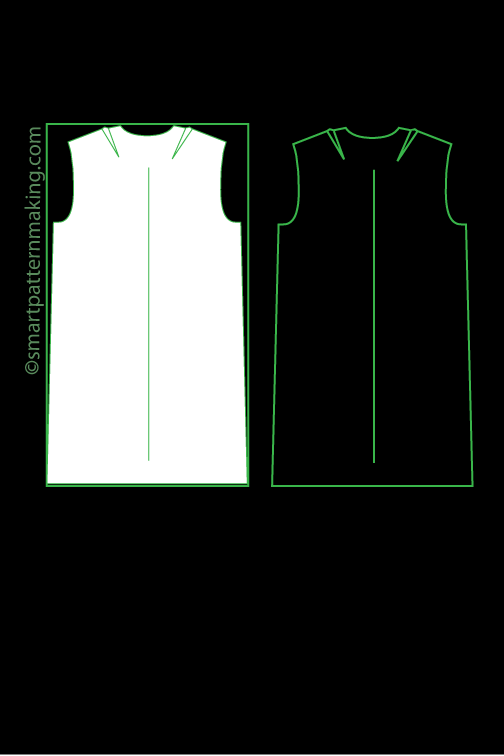

Pants and shorts grading pattern is the technique used in turning a base size or sample size which is typically a size 6 into various sizes using a size specification sheet or grading increments. These increments are referred to as garment grading rules and each specific pants and shorts industry has different grading rules. This grading technique can be a manual pattern grading process or computer pattern grading using special computer aided design software.

Pants and shorts grading is an indispensable step that are frequently undertaken by designers and pants and shorts manufacturing firms because they are majorly required to mass produce a set of specific size patterns. Pants and shorts grading ensures that pants and shorts pattern sizing would be available to fit all body sizes. By having a variety of sizes for each pants and shorts, a designer would be able to fill out his minimum pants and shorts order cost effectively. Pants and shorts grading does not create shape, it only ensures that the sizes of the pants and shorts are increased or decreased while the pants and shorts retains its original size. In pants and shorts grading, the first size pattern is usually produced in a particular size usually a size 6 and then the pants and shorts are then resized, graded up and down. A graded up pants and shorts means to increase the size while a graded down pants and shorts means to reduce the size.

The purpose of pants and shorts grading is to evenly increase or decrease the size of a pants and shorts while retaining the shape, fit, balance and scale of style details of the pants and shorts. It is essential to remember that pants and shorts grading only makes the shape of the pants and shorts larger or smaller. The process of grading doesn’t change the shape of the pants and shorts, the process of changing the shape is called pants and shorts alteration. Pants and shorts grading takes into cognizance and acknowledges the fact that individuals are different and as such have different sizes.

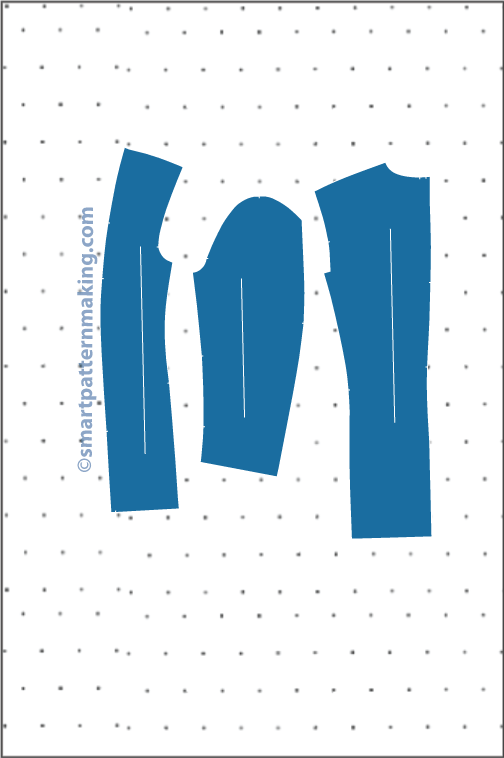

In the process of pants and shorts pattern grading, there are principally two major method being acknowledged; manual pattern grading and computer pattern grading. We shall be discussing the pros and cons of the different patterns below.

Manual Pattern Grading

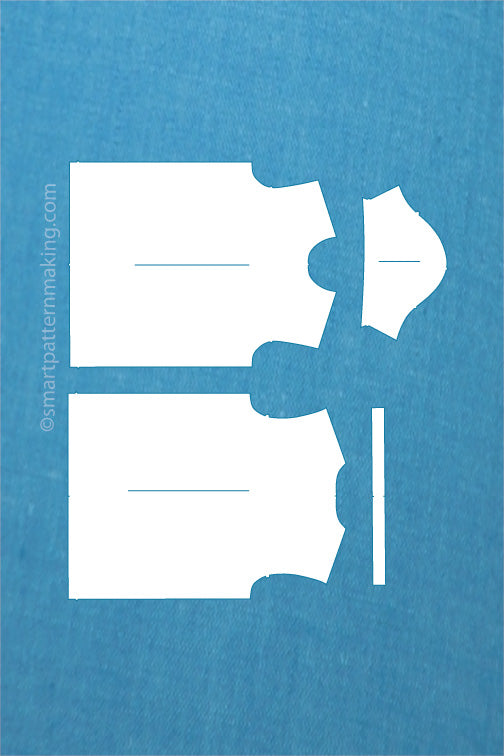

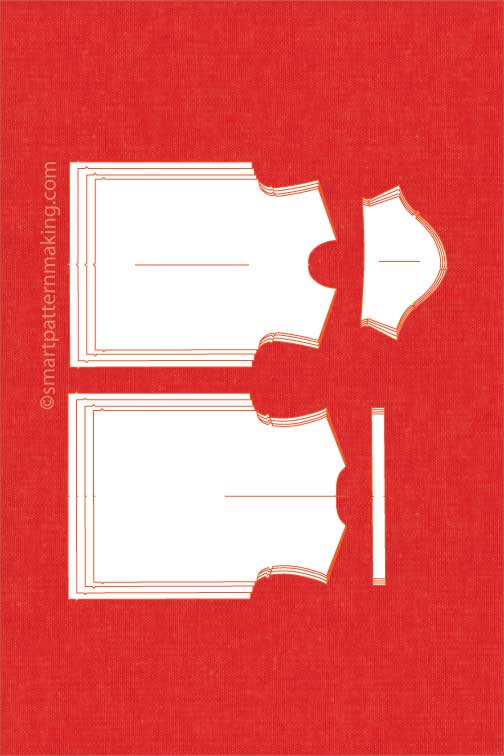

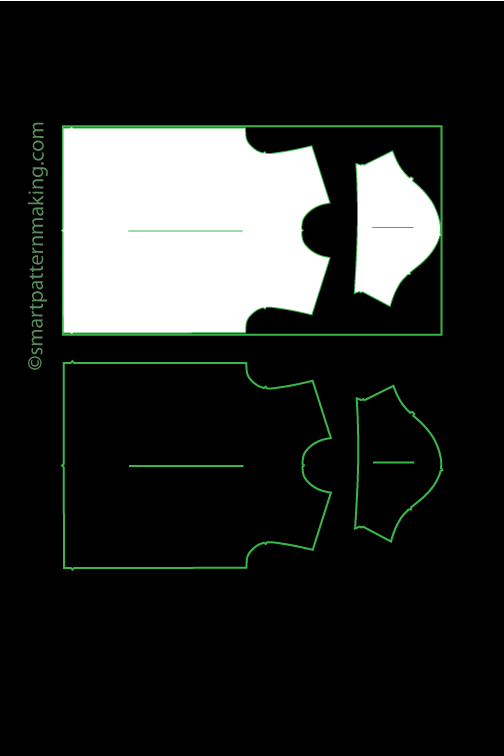

There are two ways of grading pants and shorts using the manual pattern grading; cut and spread method and the pattern shifting method. The cut and spread method involves cutting the pants and shorts and then spread the fabrics by a specified measurement to grade up or overlap the fabrics to grade down. While the pattern shifting method involves increasing the whole measurement of the pants and shorts by moving it around at an even measurement. After adjusting the measurement, the outline is then joined together around the sewing line in order to retain the shape of the pants and short.

Pros:

i. it is a cost effective process

ii. creates more employment opportunities for fashion designers in the industry

Cons:

i. it is a time consuming process

ii. the expected accuracy desired may not be achieved

iii. the grading doesn’t allow for flexibility as the designer has to physically be around to effect the resizing

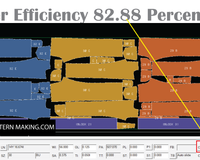

Computer Pattern Grading

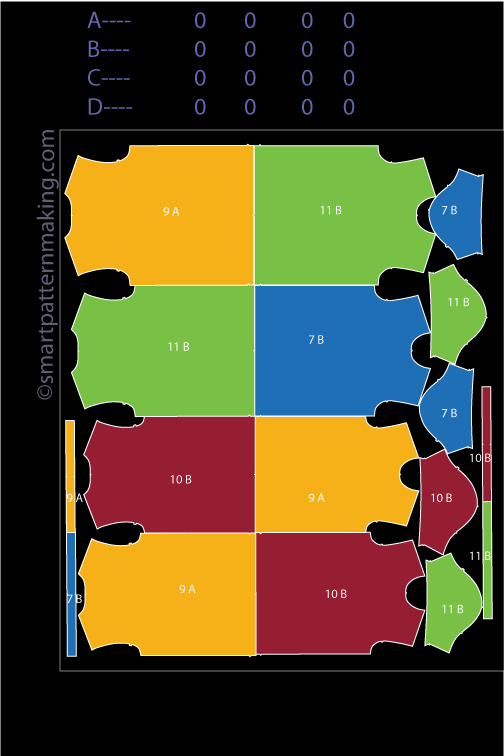

Computer pattern grading is the latest grading pattern development which has come into light as a result of the recent technological advancement going on around the world today. The computer pattern grading makes use of specially computer software usually referred to as computer aided design systems. This software allows the designer to indicate every component of a pants and shorts details and then modify each pants and shorts pattern individually until the ratio and desired measurement of the base pattern are in line with the preferred measurement wished to be adjusted. As soon as the pants and shorts pattern is uploaded or created into the computer aided design system, the system automatically begins the process of grading up or grading down the pants and shorts to the specified measurement.

Pros:

i. it is time efficient

ii. all elements of the preferred measurement wished to be graded can be easily stored ad created into the computer aided design system

iii. the grading can be done from anywhere and process can also be easily monitored by the customer

iv. the entire process can be easily modified and tailored within a short time frame without incurring any significant delay or cost

v. high accuracy is easily achieved

Cons:

i. the computer aided system operator have to constantly train themselves to meet up with the various software updates

ii. it could be a herculean task finding a skilled operator to run the computer aided design system software

iii. it is a very expensive software to obtain

Technically, there is no one method superior to the other, as both the manual pattern grading and computer pattern grading can produce the perfect fit and resizing to the pants and shorts. The choice of deciding which method to use for pants and shorts grading should spend on preference. However for mass grading of pants and shorts the computer pattern grading is effective while for singular grading of pants and shorts the manual pattern method would be preferred.

Ready to start grading your patterns? Click the get started button below. We are apparel industry pattern grader professionals with 25 plus year experience in pattern grading and resizing.

Alejandro Esparza: Co-Founder @ smartpatternmaking.com /Professional Pattern Maker/ Technical Designer/ Startup Advisor and acknowledged in the garment industry as authority in pattern making and pattern design process. He has the ability to work with small entrepreneurial companies’ private label customers and large organizations. Alejandro is a graduate of Los Angeles Trade Technical College Fashion Design Program. He has over 25 years of apparel garment industry experience and is part of Expert Ezine Articles Authors community since December 25, 2008 and has published multiple articles about the garment industry. Copyright © by Alejandro Esparza. All Rights Reserved. No part of this article may be copy or used without written Permission from Alejandro Esparza the Author.

------