Understanding PN Numbers in Fashion

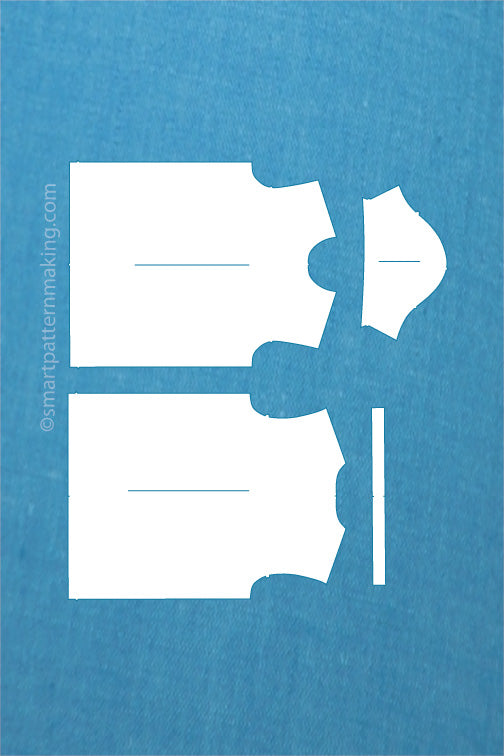

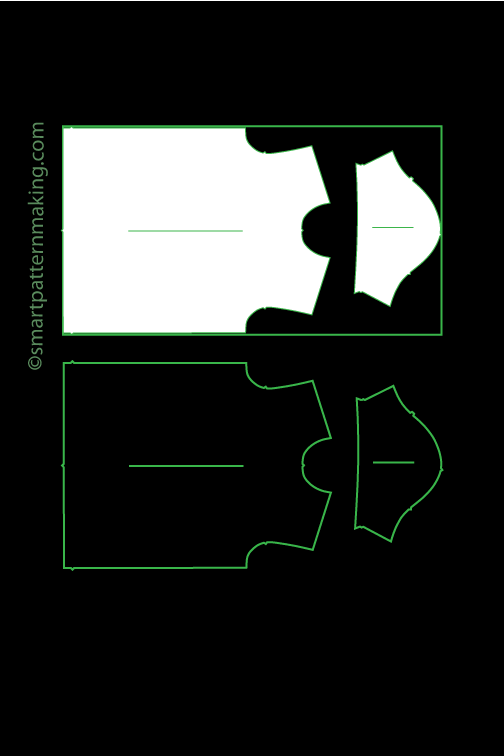

A part number—often abbreviated as PN, P/N, part no., or part #—is an identifier for a specific part design or material used in an industry. In fashion, these PN numbers (also known as piece numbers) are unique codes assigned to individual pattern pieces. Although the term “PN numbers” might seem redundant because PN already stands for “piece number,” these identifiers are essential.

What does PN mean on clothes? When you see "PN" on pattern documentation or production files, it signifies the unique identifier for that pattern piece. These codes help manage block patterns by allowing interchangeable pieces between different styles—ensuring that no two pattern pieces share the same identifier, which is critical for accuracy, consistency, and efficient production.

Why PN Numbers Matter in Production

In the fast-paced world of fashion, clear organization is essential. From initial sketches to final assembly, every phase should flow seamlessly to save time and reduce errors. A robust system for labeling, tracking, and managing pattern pieces is the backbone of efficient production.

Integrating PN numbers within a broader system allows manufacturers to achieve seamless tracking and efficient coding. This cohesive approach strengthens overall pattern management—even when handling large-scale parts—and supports the interchangeability of block patterns between different styles.

Quick Reference Table

| Aspect | Description |

|---|---|

| Consistency | Each PN number keeps labeling clear |

| Accuracy | Unique numbers prevent overlap |

| Scalability | Integrates well with pattern grading systems |

How to Organize Your Apparel Patterns with a PN Number

Proper organization begins with assigning a PN number to each pattern piece and cataloging them systematically. A reliable PN system uses PN coding to differentiate designs and employs PN tracking for streamlined updates. This approach ensures that every pattern piece is uniquely identified and fits neatly into a larger, cohesive pattern system.

Key Strategies for PN Organization

- Label each pattern piece with a unique PN number

- Centralize part numbers for easy reference

- Utilize PN coding to indicate style or size variations

PN Number Organization Chart

| PN Number | Piece Name | Category | Tracking Status |

|---|---|---|---|

| 4001 | Front Panel | Topwear | Labeled |

| 4002 | Back Panel | Topwear | Cataloged |

| 4003 | Sleeve | Topwear | PN Coded |

| 4004 | Collar | Accessories | Tracked |

| 4005 | Hem Band | Trim | Finalized |

Understanding PN Numbers in Fashion Manufacturing

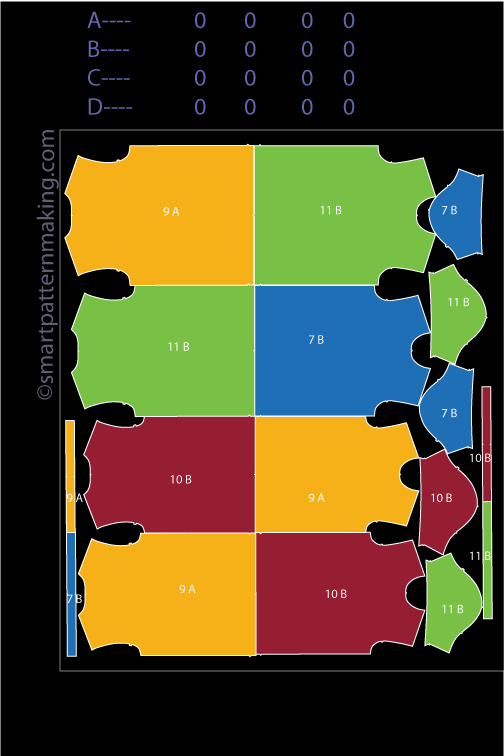

In large-scale apparel production, PN numbers keep every piece and all pattern pieces in order. By uniting them under one system, designers can implement PN coding to record design variations and employ PN tracking to monitor changes efficiently. This method pairs with a well-designed pattern system that uses unique numbers to ensure accuracy. A robust pattern grading system further enhances management by linking finished sizes to their respective part numbers, all supported by ongoing PN management.

Key Points

- Unified labeling simplifies search and retrieval

- PN coding encodes size or style data

- PN tracking helps monitor pattern history

PN Number Tracking Chart

| PN Number | Piece Name | Size | Tracking Notes |

|---|---|---|---|

| 1001 | Front Panel | Medium | Updated design v1.1 |

| 1002 | Back Panel | Medium | Graded for new fit |

| 1003 | Sleeve | Medium | Altered seam allowance |

| 1004 | Collar | Medium | Reinforced stitching |

| 1005 | Hem Band | Medium | Length adjustment |

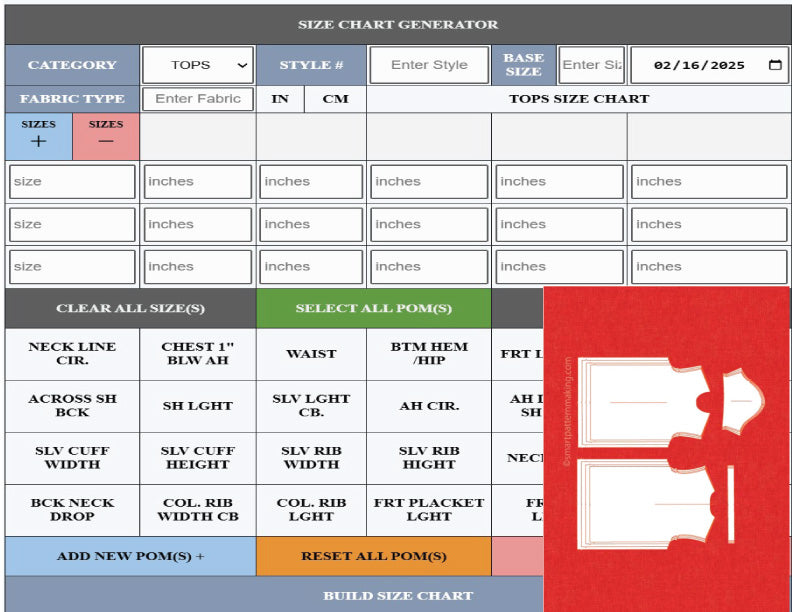

The Role of PN Numbers in Digital Pattern Management

Adopting a digital workflow calls for organized PN numbers to reference each pattern piece across design software. When integrated into a centralized system, designers can update pattern pieces in real time using PN tracking. Stored under unique numbers, digital files remain easy to identify, and PN coding allows additional sorting by style or fabric. Seamless links to a pattern system ensure that any changes sync with a supporting pattern grading system, resulting in efficient control over parts at all stages.

Sample Digital Flow

- Assign PN numbers to each design file

- Embed PN coding for quick categorization

- Track revisions with PN tracking

- Align final outputs with a robust pattern grading system

PN Digital Management Chart

| PN Number | File Name | Category | Last Update |

|---|---|---|---|

| 2001 | Front_Panel.dxf | Outerwear | 02/10/2025 |

| 2002 | Back_Panel.dxf | Outerwear | 02/09/2025 |

| 2003 | Sleeve.dxf | Outerwear | 02/08/2025 |

| 2004 | Collar.dxf | Accessories | 02/07/2025 |

| 2005 | Hem_Band.dxf | Trim | 02/06/2025 |

How a PN System Can Streamline Apparel Production

A cohesive PN system assigns every PN number to the relevant pattern pieces, making it simpler to handle multiple parts without confusion. Each pattern piece becomes part of a consistent framework, and unique numbers guarantee distinct identification. By pairing PN coding with PN tracking, teams benefit from clearer communication and reduced errors. In tandem, an overarching pattern system promotes effective PN management, while a complementary pattern grading system ensures each style is well organized.

Benefits

- Faster assembly as each piece is easily located

- Smoother scaling with a pattern grading system

- Uniform record-keeping for all design variations

PN System Efficiency Chart

| PN Number | Piece Name | Category | Status |

|---|---|---|---|

| 3001 | Front Panel | Topwear | Approved |

| 3002 | Back Panel | Topwear | In Review |

| 3003 | Sleeve | Topwear | Graded |

| 3004 | Collar | Accessories | Finalized |

| 3005 | Hem Band | Trim | Pending Approval |

PN Tracking: Enhancing Accuracy in Pattern Room Management

Real-time monitoring is where PN tracking excels. With PN numbers assigned to each pattern piece, you can locate specific pieces as needed—thanks to a structured system that supports unique identifiers. This clarity minimizes confusion between parts and, when paired with efficient PN coding and a pattern grading system, ensures that all scaling aligns perfectly across your entire pattern library.

Quick Advantages

- Swift retrieval of key pieces

- Minimal labeling errors

- Seamless integration with digital databases

PN Tracking Accuracy Chart

| PN Number | Piece Name | Tracking Status | Database Integration |

|---|---|---|---|

| 7001 | Front Panel | Located | Synced |

| 7002 | Back Panel | Updated | Synced |

| 7003 | Sleeve | Scanned | In Progress |

| 7004 | Collar | Verified | Synced |

| 7005 | Hem Band | Pending | In Queue |

PN Management: Reducing Errors in Garment Production Workflow

Solid PN management integrates each PN number into a single ecosystem, preventing mistakes from disorganized parts. By linking unique numbers to each pattern piece, confusion over overlapping designs is minimized. A structured system simplifies how teams apply PN coding, while routine tracking ensures that misaligned pieces are caught early. This consistent approach, coupled with a robust pattern grading system, streamlines production and supports seamless collaboration.

Error-Reduction Highlights

- Unified reference for all designs

- Consistent updates tracked in real time

- Adaptable to both small runs and large-scale orders

PN Error Reduction Chart

| PN Number | Piece Name | Error Type | Correction Status |

|---|---|---|---|

| 6001 | Front Panel | Incorrect Label | Fixed |

| 6002 | Back Panel | Size Mismatch | Updated |

| 6003 | Sleeve | Misaligned Pattern | Revised |

| 6004 | Collar | Duplicate Number | Reassigned |

| 6005 | Hem Band | Tracking Issue | Resolved |

How PN Coding Improves Garment Fit and Sizing Accuracy

When each PN number includes targeted PN coding, the journey from initial pattern to final product becomes more precise. By applying consistent unique numbers to every pattern piece, designers maintain orderly layouts for varying body shapes. Tools such as a pattern grading system pair naturally with PN tracking, ensuring that each size adjustment aligns with the overall system. A robust PN management process prevents mislabeling and helps keep large inventories in check.

Key Benefits

- Ensures accuracy in garment fit across all sizes

- Reduces errors by maintaining consistent PN tracking

- Streamlines pattern adjustments within a grading system

PN Coding & Sizing Accuracy Chart

| PN Number | Piece Name | Size Category | Adjustment Status |

|---|---|---|---|

| 5001 | Front Panel | Small | Graded |

| 5002 | Back Panel | Medium | Graded |

| 5003 | Sleeve | Large | Adjusted |

| 5004 | Collar | All Sizes | Standardized |

| 5005 | Hem Band | Custom Fit | Finalized |

Conclusion

Whether you’re an emerging designer or a seasoned manufacturer, maintaining clear labels and organized structures is crucial for efficient garment production. By assigning each pattern piece a PN number, leveraging PN coding for quick identification, and adopting PN tracking to stay up-to-date, you can bring order to the often-chaotic fashion workflow. Introducing unique numbers further eliminates confusion, while a comprehensive pattern grading system ensures sizing remains precise. A well-designed PN system not only simplifies pattern management but also supports seamless collaboration across teams. Embrace this cohesive approach to gain a competitive edge, reduce errors, and deliver superior apparel in today’s demanding market.

Elevate Your Apparel Design with Precision Pattern Management

Take control of your pattern creation and production with our comprehensive tools and services. From designing your custom patterns to converting them into digital files, resizing, converting to DXF format, or printing, we provide the best solutions for your business needs. Get started today and streamline your workflow!

Related:

-

Aerospace:

"Aerospace PN Numbers: Turbofan Component Coding for Precision" -

Automobile:

"Automotive PN System: Engine Parts Tracking for Efficiency" -

Furniture:

"Furniture PN Numbers: Sofa Parts Coding for Accuracy" -

Apparel:

"Apparel PN Management: Running Shoe Component Numbers for Performance" -

Fashion:

"PN Numbers & PN System: Streamlining Fashion Pattern Management"

Loved reading this article and found it valuable? Show us some love and buy us a coffee! ☕ :)

Developing tools and creating valuable content requires countless hours of work and extensive research—ensuring you have them at your disposal. Additionally, keeping this site ad-free and covering operational expenses demands significant resources.

If our work helps you, please consider supporting us. Your donation allows us to continue providing more valuable tools, fresh content, and top-notch services.

Thank you so much for your support!

-------------------