When looking for a garment that fits great in a boutique or high end department store many times people don’t always find a garment that fits their body properly. The problem is due to three pattern-making problems: bad Pattern balancing, wrong pattern proportions and incorrect pattern adjustments when fitting a garment on a live model.

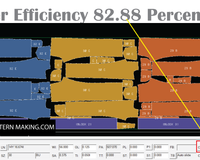

Pattern Making Problem 1). Balancing. When designing a garment pattern balance plays a major role in the way a garment fits on a person’s body. A not well balance pattern can cause a garment to look poorly fitted or unpleasant to the client’s eye due to the way it hangs on a hanger. A pattern that is off grain line not align properly on the fabric’s grain line can cause a garment to swing toward one side more than the other side.

Pattern Making Problem 2). Wrong pattern proportions. Now days many designs signatures create designs that do not reflect true body measurements or proportions. This problem is best seen when people go shopping and do not find a garment that fits them properly either because the design is too big overall or the bust measurement of a dress is too small and the hip area too big. Making a pattern for a design with not standard specifications available will dramatically affect the fit of a design by making it not wearable due to the patterns proportions wrongly used. Another common problem when making a pattern for a particular costumer or market is the lack of a professional model hired by a company or designer. This can be a very problematic issue in pattern making because not having an actual model as a base size and using different models will change the proportions of a pattern for a particular design.

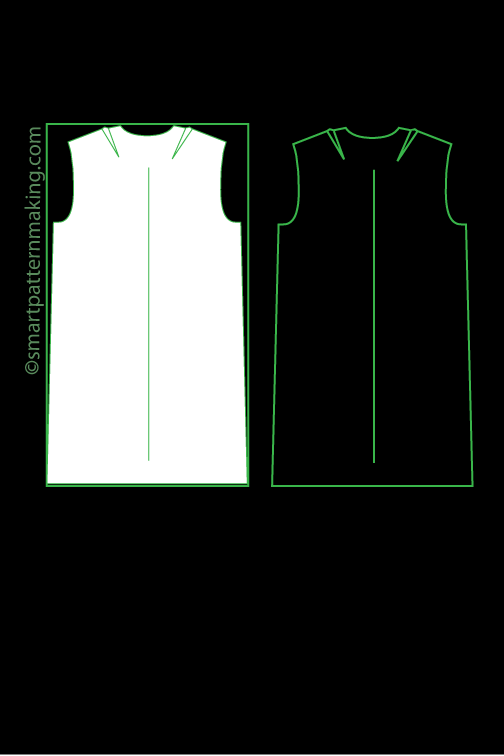

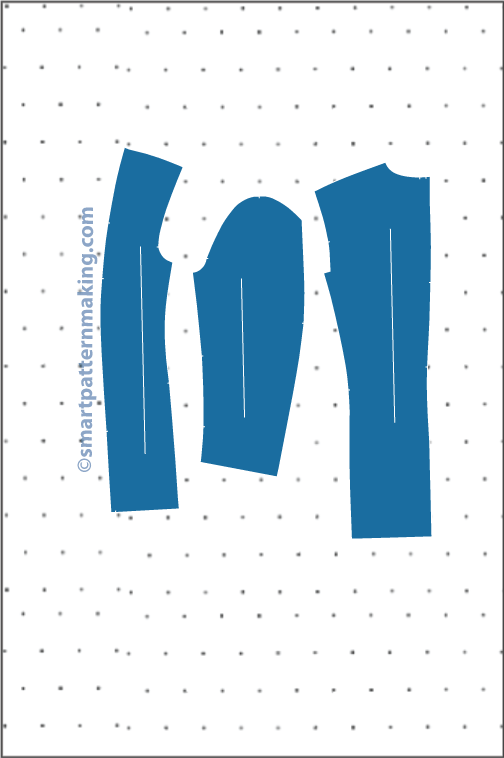

Pattern Making Problem 3). Incorrect pattern alterations. Not knowing correct pattern drafting techniques and proper pattern alterations when fitting a garment on a live model will return poor fitted garments. Experienced pattern makers now days use technology to create patterns but often in times many pattern corrections are not made properly due to the lack of manual pattern manipulation experienced. It is imperative that pattern corrections made to a pattern must be tested for accuracy and fit before releasing a pattern for production.

In Summary, Many High-end department stores do not always have the best-fitted garments in their stores. Costumers have a hard time finding a well-fitted garment and patterns made for a particular design are not been fitted properly. Incorrect pattern balancing, not true proportions and lock of knowledge about how to fix a pattern on a real live model will all contribute to poor fitted garments. Following industry standards and making the proper research about body proportion of a particular population will dramatically improve the way a garment fits on a person’s body. A conscious or well-established company who hires professional experienced pattern makers and fit models will benefit from their investment the most by getting compliments and sales on all the designs they create no matter of its size or the number of years it has been in business.

About the Author

Alejandro Esparza: CO-Founder@smartpatternmaking / Professional Pattern Maker/ Technical Designer/Consultant and acknowledged in the garment industry as authority in pattern making and pattern design process. He has the ability to work with small entrepreneurial companies’ private label customers and large organizations. Alejandro is a graduate of Los Angeles Trade Technical College Fashion Design Program. He has over 25 years of apparel garment industry experience and is part of Expert Ezine Articles Authors community since December 25, 2008 and has published multiple articles about the garment industry.

------------------------------------------------------------------------------------------

1 comment

Chandran

Please note I know how solve those three problems. Since have very good work experience in manual as well as tailoring as traditional way