Introduction

In the fast-paced world of garment manufacturing, efficiency and standardization are key to staying competitive and profitable. General Sewing Data (GSD) provides a systematic approach to determining the standard time required for various sewing operations, helping manufacturers optimize their processes, reduce costs, and ensure fair labor practices. This guide will explore the importance of GSD, its application in the industry, and how to get trained and certified to leverage this powerful tool effectively.

What is General Sewing Data (GSD)?

GSD is a method used to determine the standard time required for sewing operations. It provides a systematic approach to setting time standards for different sewing tasks, ensuring consistency and accuracy across production lines. GSD helps manufacturers optimize their production processes, reduce costs, and enhance overall efficiency.

Importance of GSD in the Garment Industry

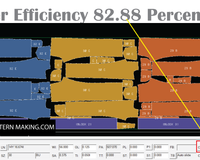

- Standardization: GSD provides a uniform system for measuring and evaluating sewing tasks, ensuring that all operations are performed to the same standard.

- Productivity Improvement: By identifying and eliminating inefficiencies, GSD helps manufacturers improve their production rates and reduce waste.

- Cost Reduction: Accurate time standards enable better labor costing and budgeting, helping manufacturers control costs.

- Fair Compensation: GSD ensures that workers are compensated fairly based on the time and effort required for each task, promoting fair labor practices.

- Incentive Schemes: GSD data can be used to design effective incentive schemes that motivate workers to achieve higher productivity levels.

How GSD Works

GSD involves a detailed analysis of each sewing operation to determine the standard time required for its completion. This process includes:

- Task Observation: Recording the time taken to complete a task under typical working conditions.

- Performance Rating: Assessing the operator’s speed and consistency to determine a rating factor.

- Standard Time Calculation: Multiplying the observed time by the rating factor to get the standard time.

Getting Trained and Certified in GSD

Training Options:

- Company Training: GSD systems are typically sold to companies that then receive training for their industrial engineers. This training ensures that the company can effectively implement GSD in their production processes.

- Direct Training from GSD: Individuals or companies can contact GSD directly for practitioner training. This training includes comprehensive exposure to GSD codes, times, and application rules.

Certification Programs:

- GSD Practitioner Certification: This program includes theoretical and practical exercises to ensure accurate and consistent work measurement. It adheres to the guidelines set by the International Labour Organisation (ILO).

--------------------------

Key Contacts for GSD Training

- In India: Garment manufacturers can contact IIGM for details about GSD services and training programs.

- In the UK: Contact Coats Digital directly for training opportunities and certification programs.

-

In Australia Australian garment manufacturers can reach out to TAFE NSW for GSD training services.

- In the USA: Manufacturers can contact AITEX America for information on GSD services and training programs.

Conclusion

Implementing General Sewing Data (GSD) into your garment manufacturing processes can significantly enhance productivity, reduce operational costs, and promote fair labor practices. By understanding and applying GSD standards, manufacturers can achieve higher efficiency, streamline operations, and create a more equitable working environment. Whether you're looking to improve your production rates or ensure fair compensation for your workers, GSD is an essential component of modern garment manufacturing. Embrace GSD today to stay ahead in the competitive market and drive continuous improvement in your operations.

References

- Coats Digital (GSDCost)

- Garment Technology Expo

- International Labour Organisation (ILO) Guidelines ---------------------------

Incorporating GSD into your operational strategy is crucial for achieving high levels of productivity and efficiency. By standardizing procedures, training observers, and leveraging technology, businesses can ensure accurate and fair performance assessments. This not only leads to better resource management and fair compensation but also drives continuous improvement in operational processes, setting the foundation for sustained success and competitiveness in the industry.

---------------------------------

You Might Want To Also Read Related Articles Below:

- Mastering Garment SAM Calculation: A Step-by-Step Guide

- Performance Rating: Assessing the Operator's Performance Level

- Simplifying General Sewing Data (GSD) for the Clothing Industry

- Boost Garment Efficiency with General Sewing Data (GSD) Training"

- Understanding Time Measuring Unit (TMU): Standard Time and Motion Study

- How to Collect Sewing Performance Data (SPD)

- Best Tools for Collecting Sewing Performance Data (SPD)

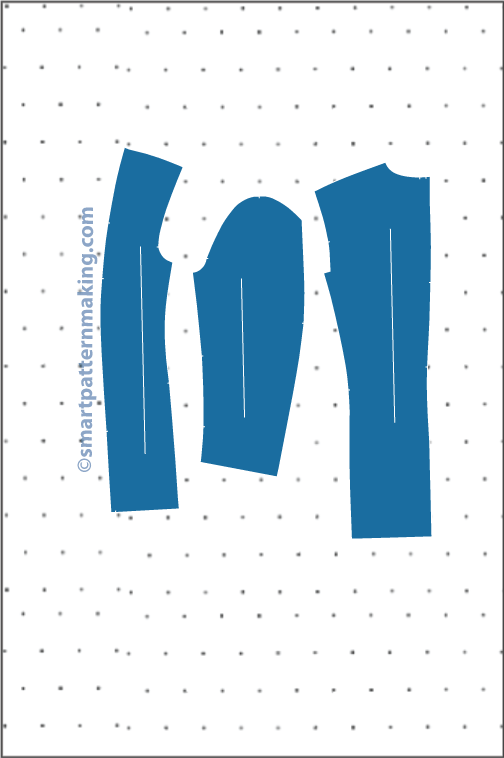

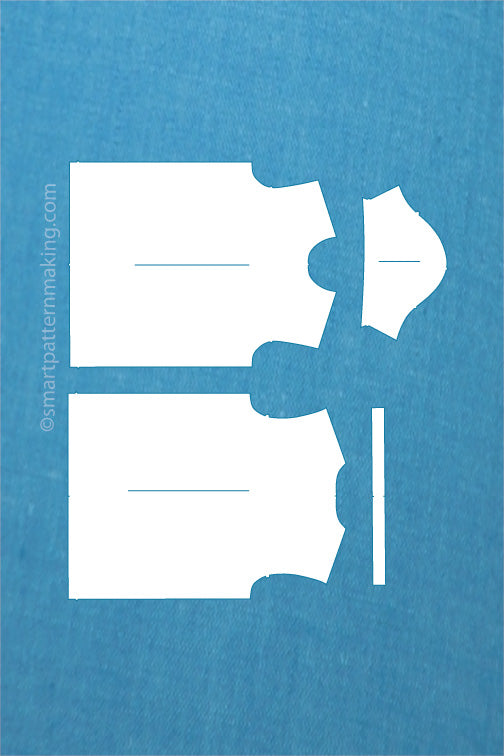

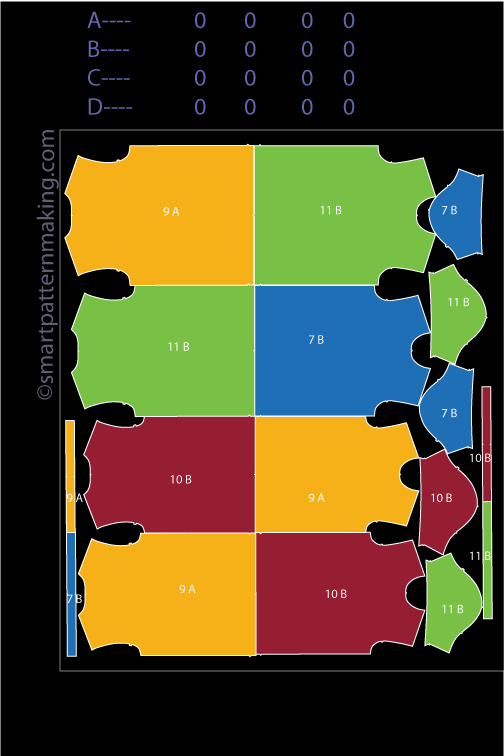

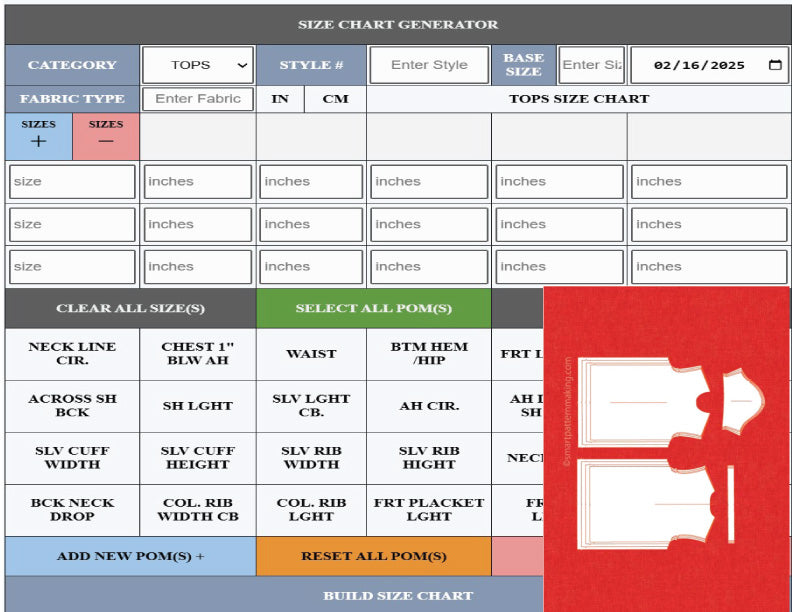

Ready to boost garment efficiency and create your own patterns or garment styles? Drop us a chat NOW and we’ll get you started!

Discover all of our Pattern Making, Digitizing, Resizing and Printing services . Let our expert team help you create your next personal or business apparel clothing designs today!

Loved reading this article and founded valuable? If so, Show us some love and buy us a coffee! ☕ :)

Developing tools and creating valuable content takes a lot of hours of work and days of research so that you can have them at your disposal. Also, keeping the content you read (Ads FREE) and operating this website cost a lot of money. So please, consider supporting us, so that we might continue to provide you with more valuable tools, fresh content, and to continue offering you with the best services that you deserve!