Introduction

In the fast-paced and highly competitive world of garment manufacturing, optimizing efficiency and accuracy is paramount. One of the key tools used to achieve this is the Time Measuring Unit (TMU). Understanding TMU, particularly within the context of Methods Time Measurement (MTM) systems and motion studies, is essential for professionals looking to improve their manufacturing processes. This article delves into what TMU is, its conversion to familiar time units, its application in the apparel industry, and why mastering this metric can lead to significant productivity gains.

What is TMU in Time and Motion Study?

TMU, or Time Measuring Unit, is a pivotal metric in Methods Time Measurement (MTM) systems, where each motion in a work process is assigned a predetermined time. This unit is crucial for motion studies as it helps quantify the time required for each basic element of work. Accurate time measurement is fundamental to time and motion studies as it provides the data needed for efficiency measurement.

How Many TMUs in a Second and a Minute?

The conversion of TMU to more familiar time units is straightforward:

- 1 TMU = 0.000010 hours = 0.00060 minutes = 0.036 seconds

Conversely:

- 1 second = 27.78 TMUs

- 1 minute = 1667 TMUs

- 1 hour = 100,000 TMUs

Accurate time conversion ensures that the time unit conversion from TMUs to seconds, minutes, and hours is precise, which is essential for effective time management techniques.

Application of TMU in the Apparel Industry

In the apparel industry, TMUs are essential for establishing the Standard Allowed Minute (SAM) for sewing operations using the Predetermined Motion Time Systems (PMTS). Each motion in the sewing process is assigned a time value in TMUs. Initially, standard times are calculated in TMUs, which are then converted into minutes for practical use. This standard minute calculation is critical for manufacturing efficiency.

Why TMU Matters

Understanding and applying TMUs allows for precise time management and efficiency in manufacturing. By breaking down each task into its basic motions and measuring the time for each, companies can streamline operations, reduce costs, and improve productivity. This process involves detailed time unit conversion to ensure accuracy in time measurement.

TMU and Standard Time in Motion Study

The use of Time Measuring Unit (TMU) is integral to achieving a standard time for various work elements. In a time and motion study, each work element's time is recorded in TMUs. This standard minute calculation helps in setting benchmarks and improving manufacturing efficiency. Accurate time unit conversion from TMU to minutes or seconds ensures that time measurement is precise, facilitating better time management techniques.

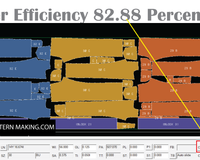

Enhancing Manufacturing Efficiency with TMU

By applying TMUs, manufacturers in the apparel industry can enhance efficiency measurement. The time measurement for each sewing operation, when broken down into standard time units, helps in better workflow management. The time unit conversion from TMUs to minutes aids in creating an accurate timeline for each task, ensuring every motion study contributes to overall efficiency.

Implementing TMU in Time and Motion Study

When conducting a time and motion study, the primary goal is to identify and eliminate inefficiencies. By using TMUs to measure the time for each work element, manufacturers can achieve significant improvements in manufacturing time study. This process involves detailed time unit conversion to ensure accuracy in time measurement.

Practical Steps for Using TMU

- Select Operation: Choose the specific operation for which you want to calculate the standard minute.

- Study the Motions: Observe an experienced operator performing the operation. Note every movement they make during a complete work cycle.

-

List and Convert Motions:

- List all movements sequentially.

- Refer to synthetic data sources like General Sewing Data (GSD) or Sewing Performance Data (SPD) for Time Measuring Unit (TMU) values.

- Convert TMU to minutes (1 TMU = 0.00060 minutes). This gives you the basic time.

-

Calculate SAM:

- Add bundle allowance (10%) and personal and machine allowances (20%) to the basic time.

- Formula: SAM = Basic Time + (Basic Time × 10%) + (Basic Time × 20%)

Example Calculation

- Basic Time = 0.24 minutes

- Bundle Allowance = 0.024 minutes

- Personal and Machine Allowance = 0.048 minutes

- SAM = 0.24 + 0.024 + 0.048 = 0.31 minutes

Conclusion

Mastering the concept of Time Measuring Unit (TMU) and its application in time and motion studies is crucial for anyone involved in garment manufacturing. By leveraging TMUs, companies can establish accurate standard times, optimize workflows, and enhance overall efficiency. This understanding not only leads to cost reduction but also positions businesses to maintain a competitive edge in the industry. Embracing TMUs in your manufacturing processes is a step towards achieving greater precision and productivity.

By following these time management techniques and integrating efficiency measurement into your workflow, you can ensure that your manufacturing time study yields significant improvements in manufacturing efficiency. The precise time unit conversion and detailed time measurement provided by TMUs make them invaluable tools in any motion study.

------------------------

You Might Want To Also Read Related Articles Below:

- Mastering Garment SAM Calculation: A Step-by-Step Guide

- Performance Rating: Assessing the Operator's Performance Level

- Simplifying General Sewing Data (GSD) for the Clothing Industry

- Boost Garment Efficiency with General Sewing Data (GSD) Training"

- Understanding Time Measuring Unit (TMU): Standard Time and Motion Study

- How to Collect Sewing Performance Data (SPD)

- Best Tools for Collecting Sewing Performance Data (SPD)

Ready to boost garment efficiency and create your own patterns or garment styles? Drop us a chat NOW and we’ll get you started!

Discover all of our Pattern Making, Digitizing, Resizing and Printing services . Let our expert team help you create your next personal or business apparel clothing designs today!

---------------------------------------

Loved reading this article and founded valuable? If so, Show us some love and buy us a coffee! ☕ :)

Developing tools and creating valuable content takes a lot of hours of work and days of research so that you can have them at your disposal. Also, keeping the content you read (Ads FREE) and operating this website cost a lot of money. So please, consider supporting us, so that we might continue to provide you with more valuable tools, fresh content, and to continue offering you with the best services that you deserve!